QUALITY

Quality Policy

Quality Certifications

In the year 2000 we made the following reflection: “If we wanted to be competitive the ISO 9001 certification was without doubt an indispensable requisite to strengthen the organization and its business relationships, constituting a key pillar to sustain the durability of our organization”. Thus, in the year 2001 we were certified by the Lloyd’s Register Quality Assurance in ISO 9001:2015

The benefits obtained with it are clearly identifiable:

- Improvement of the key points in the organization

- Strengthening of the organization

- Implementation of an effective quality management system that allows the reduction of rejections and incidents, the increase of productivity and a bigger compromise with the client.

- Marketplace positioning

- Competitive advantages against other companies in the sector

- Maximum effectiveness of the products or services offered by the company.

Along the same lines and with the objective of diversifying our fabrication and entering new markets, in the year 2015 we were certified in EN-1090-1:2009 to manufacture metallic structures with CE marking, essential requisite for all manufactured products that are to be permanently incorporated in construction work, buildings as well as civil work, for the European Union (European Directive of Construction Products).

In September 2021 we obtained the ISO 3834-2 certification that guarantees an adequate control of the welding processes, facilitating the fulfillment of the quality and contractual requirements of our clients, contemplating all aspects of manufacturing, welding, personnel competence and feasibility.

Quality Department

Fully equipped laboratory for testing and inspecting the entire production process, with trained and accredited personnel.

- HandySCAN 3D Scanner

- Tensile-Compression equipment

- Micrometers

- 3D Level Calipers and Verniers

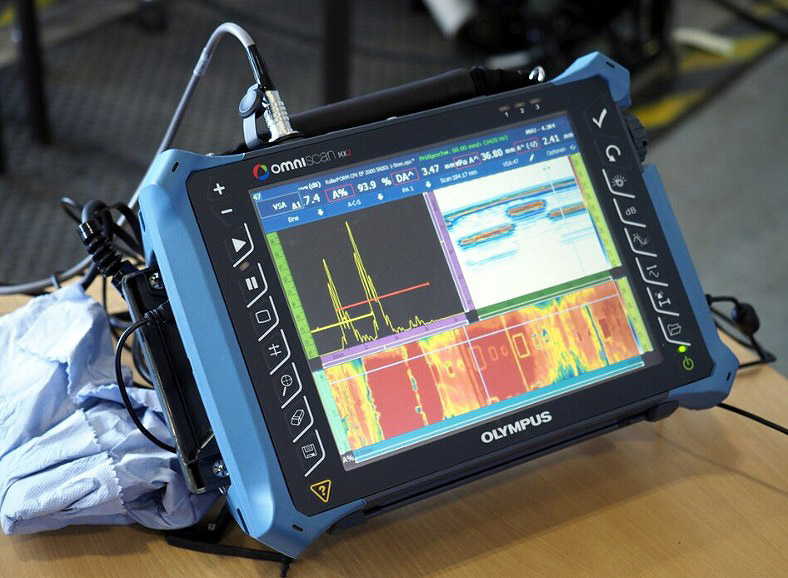

- Olympus OmniScan SX equipment

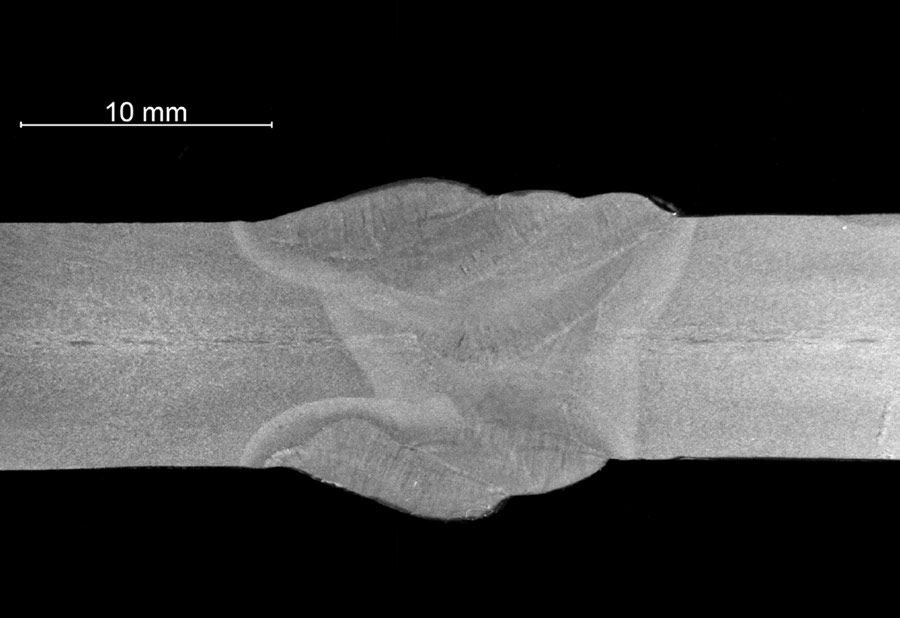

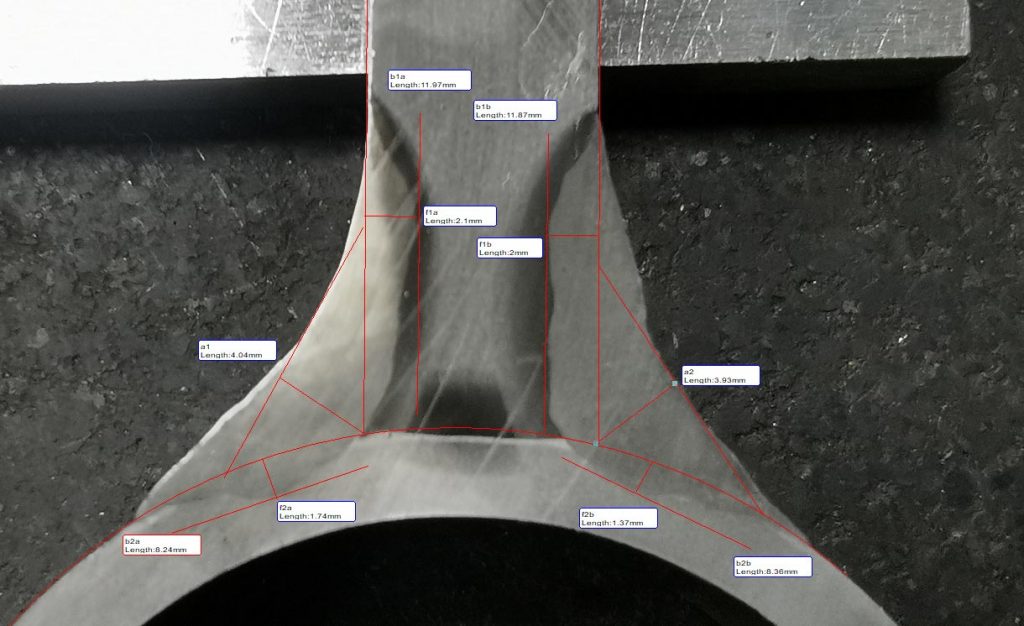

- Macroscopic technology for identifying defect distributions or discontinuities in welded joints through Mock-Up specimen examination involving cutting and fine grinding techniques.

Inspection and Testing

Visual inspection is a non- destructive testing method that allows the detection of discontinuities that affect the visually accessible surface of the objects.

Visual inspection isn’t only important as a testing method, it is also essential as preliminary testing in the execution of everything, as it always has to take place, even when the execution of other testing is planned.

To be able to carry out the visual testing effectively, it’s as important to know how to technically carry out the visual observation as knowing how to interpret the observed results. The knowledge of materials, fabrication process and the usage of the components is essential.

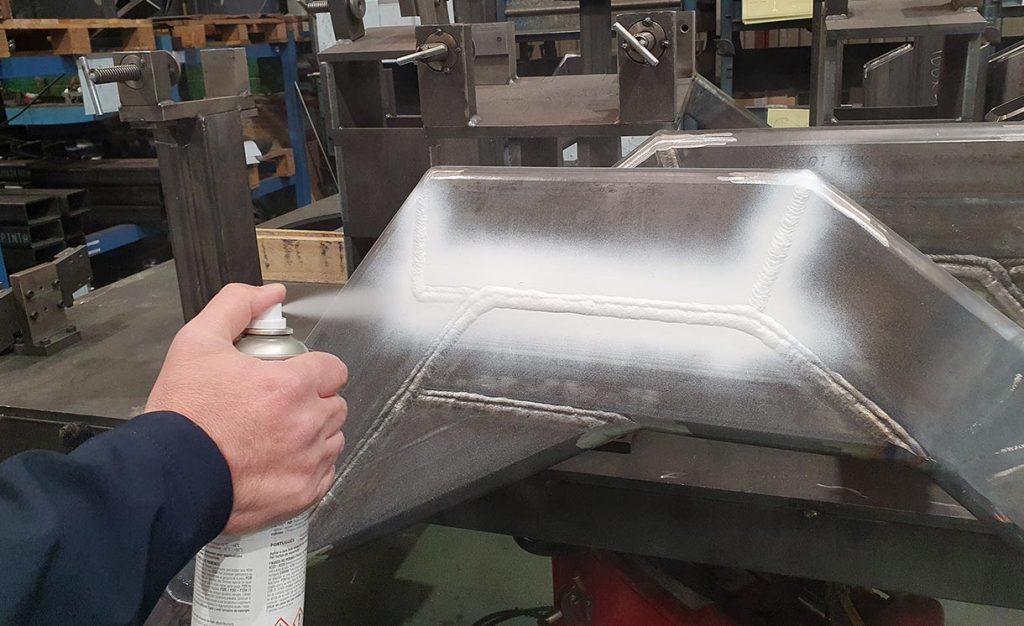

Testing by penetrating liquids is based on a system comprised of a penetrator, a method of penetrator excess disposal and a developer, which provides visible indications of the discontinuities open to the surface in non-porous materials.

The trial by magnetic particles is based on the application of a magnetic field to the object of study’s component, in that way, through the application of finely divided ferromagnetism particles, we are able to detect superficial discontinuities and/or sub superficial in magnetizable materials.

Metallographic testing is a way to conduct the evaluation of the macrostructure of components and materials.

Understanding evaluation as the determination of deterioration or damage suffered by a material as consequence from the manufacturing process or determined service.

In SV, we undertake metallographic replicas in different materials and components. For this, we have sanding and polishing equipment for the superficial preparation of the component before conducting the testing.

We make sure of the quality of the replica through observation and through our optical microscope. For the completion of the replicas we use the necessary reagents and materials to ensure good quality in the execution of the project.

Detection of internal discontinuities, such as pores, cracks, or lack of fusion in welded joints, without damaging the analyzed material.

The main advantages are:

- High capability for detecting internal defects.

- Accurate measurement, location, and depth assessment of defects.

- Applicable to thick materials and complex structures.

- No radiation required, unlike X-rays or Gamma rays.

Technical Staff accreditations

Since our beginnings, we have sought to give a significantly qualitative approach to our products and to the work carried out by the different areas of the business group. We understand Quality as the only path to success and excellence. Following this line we count in our technical staff with personnel with the following accreditations:

- Two International Welding Engineers (IWE: International Welding Engineer)

- Certified Welding Inspector (AWS-CWI 16082121) – American Welding Society (AWS)

- Level II UNE-EN-ISO 9712 Magnetic Particle Testing – CERTIANED

- Level II UNE-EN-ISO 9712 Liquid Penetrant Testing – CERTIANED

- Level II UNE-EN-ISO 9712 Visual Inspection – CERTIANED

- Level II UNE-EN-ISO 9712 Ultrasonic Testing – CERTIANED

- Welded Construction Inspector Level II No. 1497 – Spanish Association of Welding and Joining Technologies (CESOL)

- CWI Endorsement AWSD17.1 – Welding Code for Aerospace Applications

- Visual Inspector ACCP Level II Certified by ASNT – American Society for Nondestructive Testing

- Welding Supervisor Certificate for CSA STANDARD W47.1