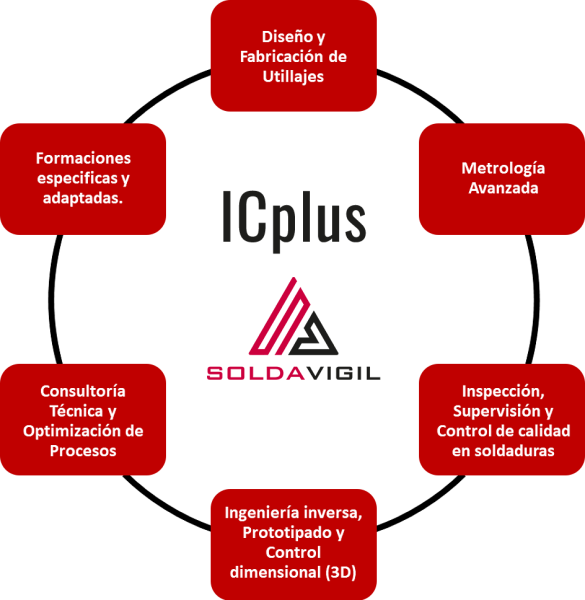

ICplus Consulting

Consulting in Engineering and Quality

"Evidence-Based Engineering"

With over 30 years of industrial experience across various sectors, our learning curve has solidified our expertise in Engineering and Quality. Combined with highly skilled human resources and advanced technology, we offer the following services tailored to companies that cannot address these needs internally.

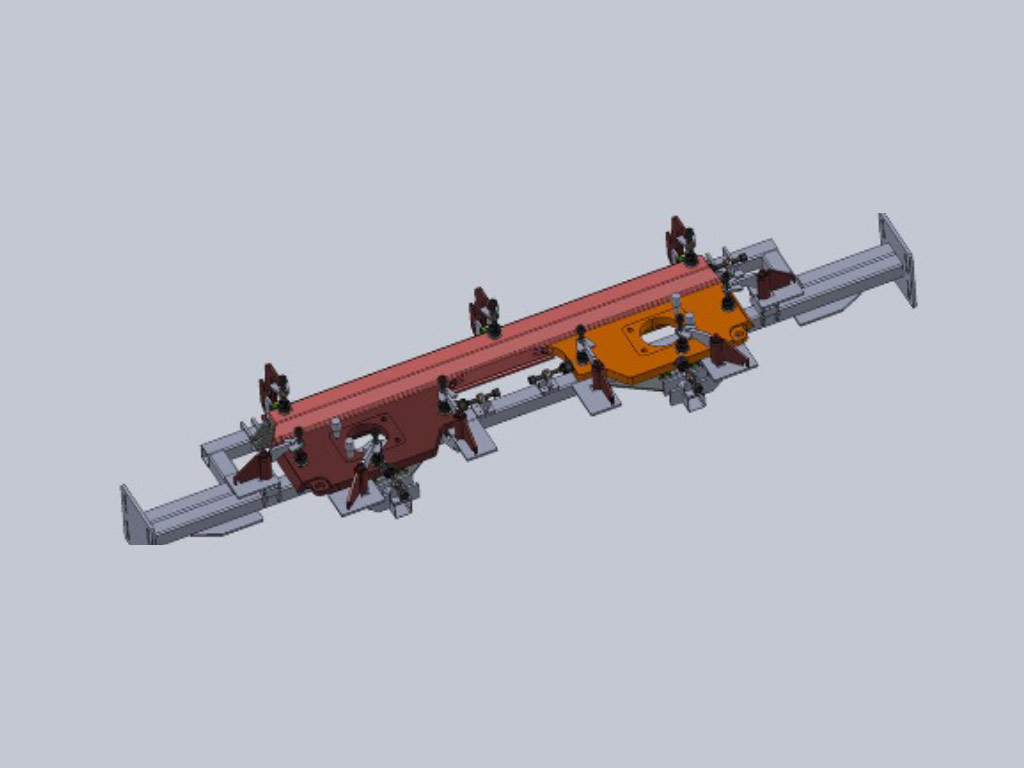

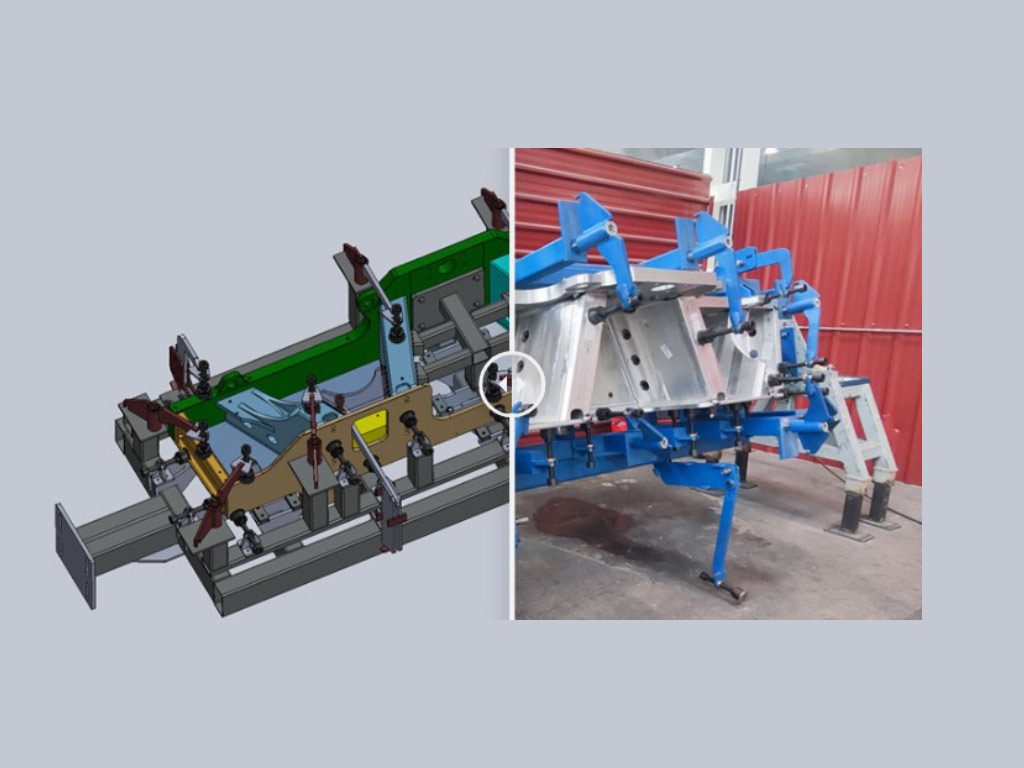

Design and Manufacturing of Tooling

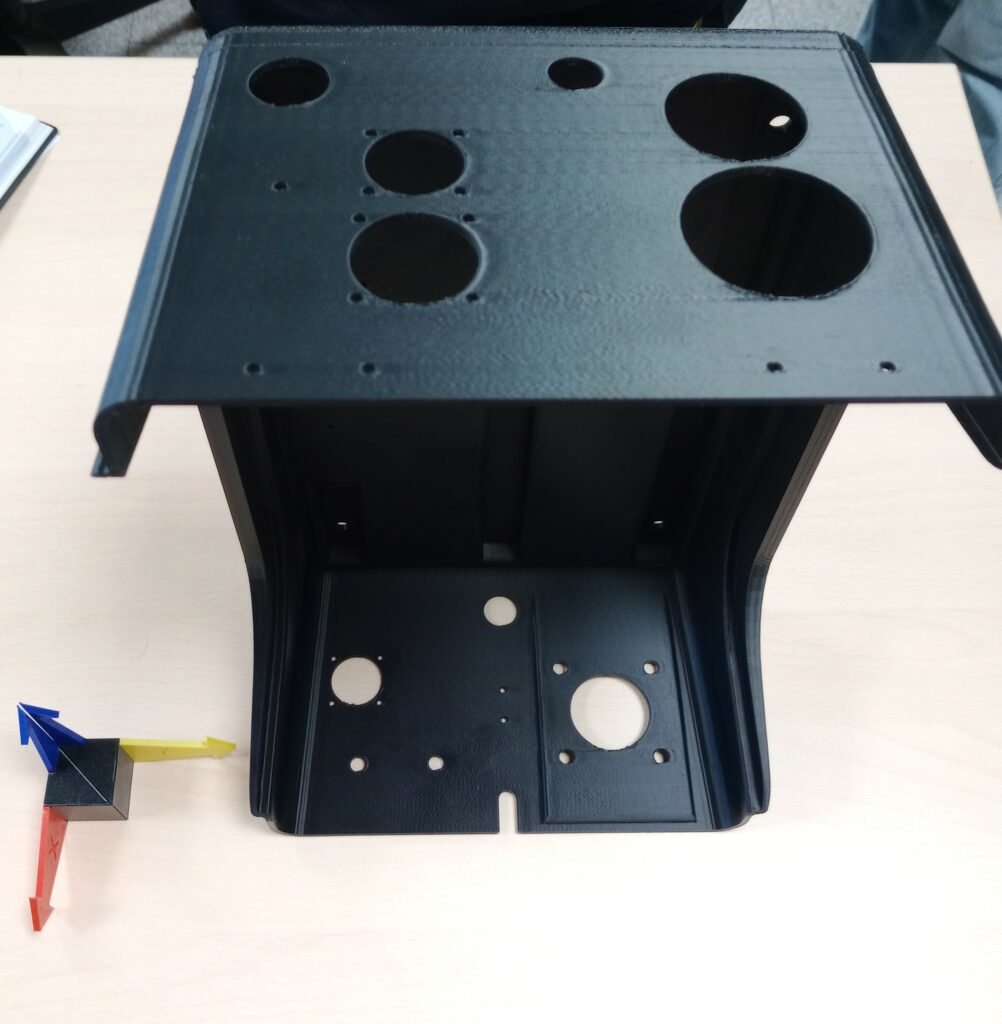

Custom tooling development for assembly, welding, and verification processes, integrating 3D printing and advanced dimensional control.

Specific Services

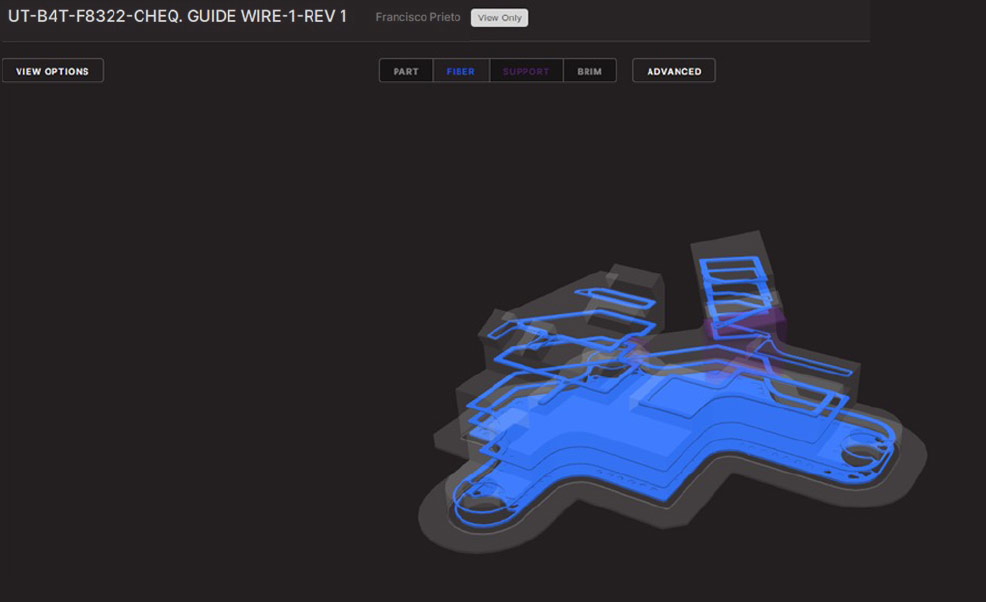

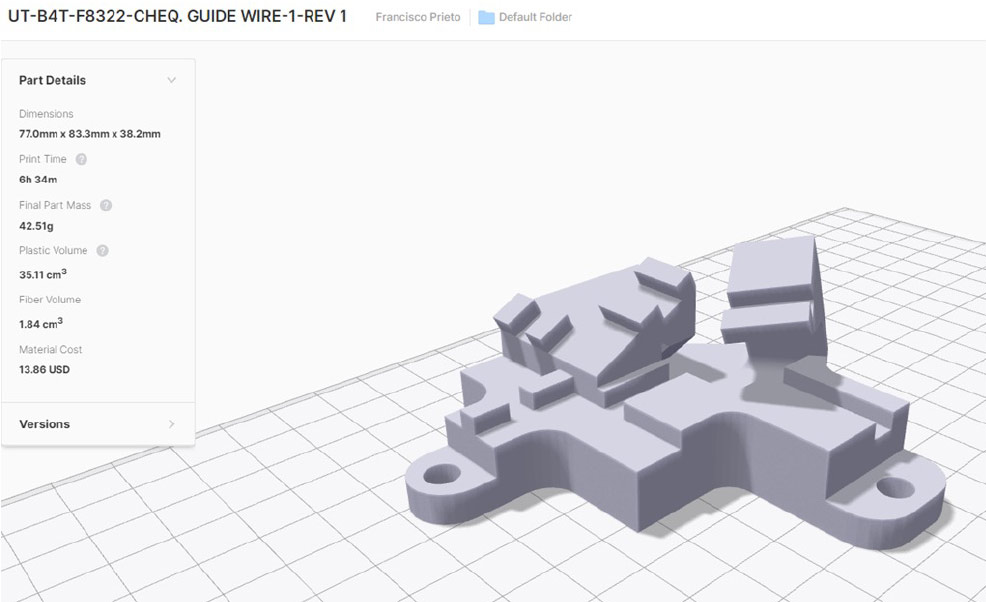

- 3D design with SolidWorks Premium

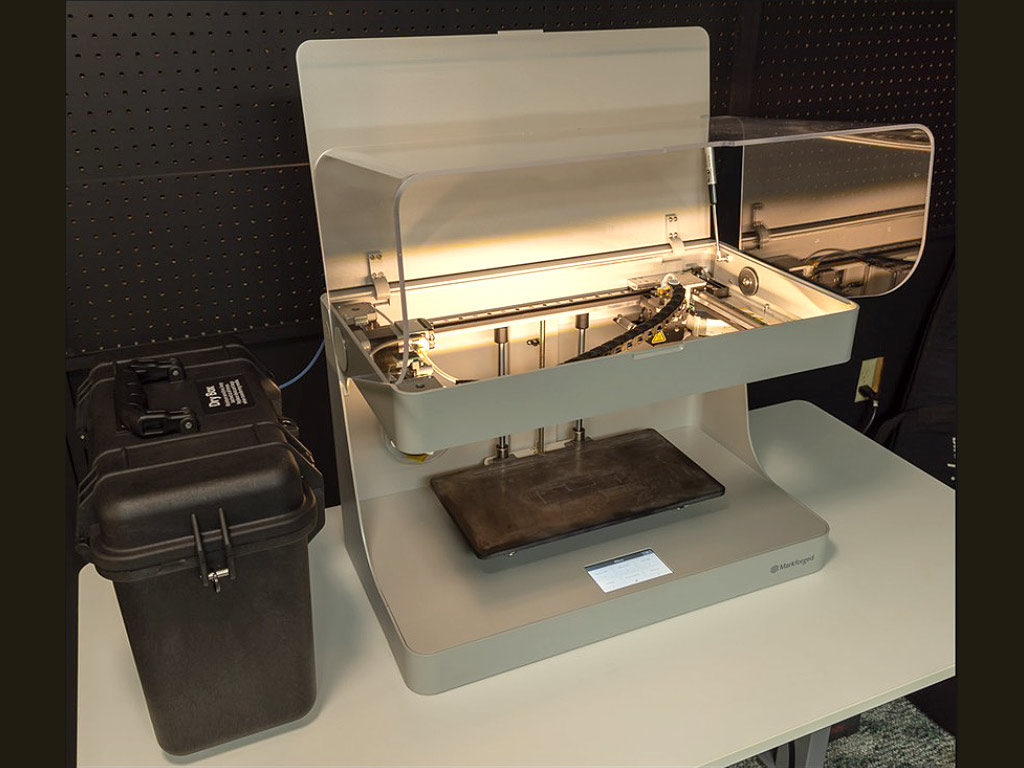

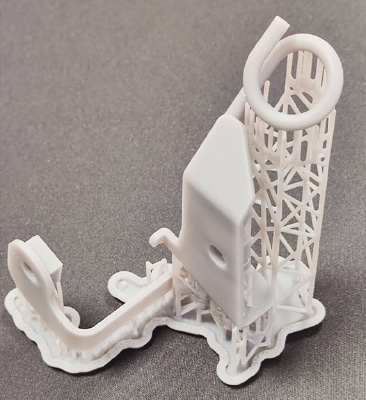

- Rapid prototyping using Markforged Mark Two (Onyx reinforced with continuous carbon fibers); high-strength SLA and FDM processes.

- Dimensional verification with HandySCAN 3D laser scanner and micrometers/calipers, ensuring tolerances of 0.01 mm.

- Technical documentation (Reports and Drawings)

Inspection, Supervision, and Quality Control in Welding

Inspection, non-destructive testing, and qualification of welding procedures and welders, backed by highly qualified and accredited personnel.

Specific Services

Welding Inspection and Supervision

- Procedure qualification (TIG, MIG, MAG) with UNE-EN, AWS (CWI), and IWE (International Welding Engineer) certifications.

- Quality supervision in welding processes (ISO 3834-2, EN 1090, EN 15085-CL1).

Non-Destructive Testing (NDT) linked to project industrialization monitoring

- Liquid Penetrant, Magnetic Particles, and Ultrasonics (UNE-EN ISO 9712, ASNT TC-1A certified).

- ACPP by ASNT.

- Certified Visual Inspection.

Advanced Metrology Analysis

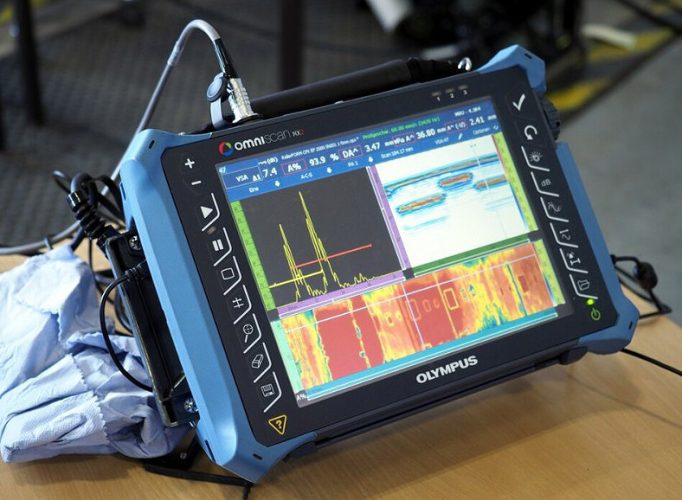

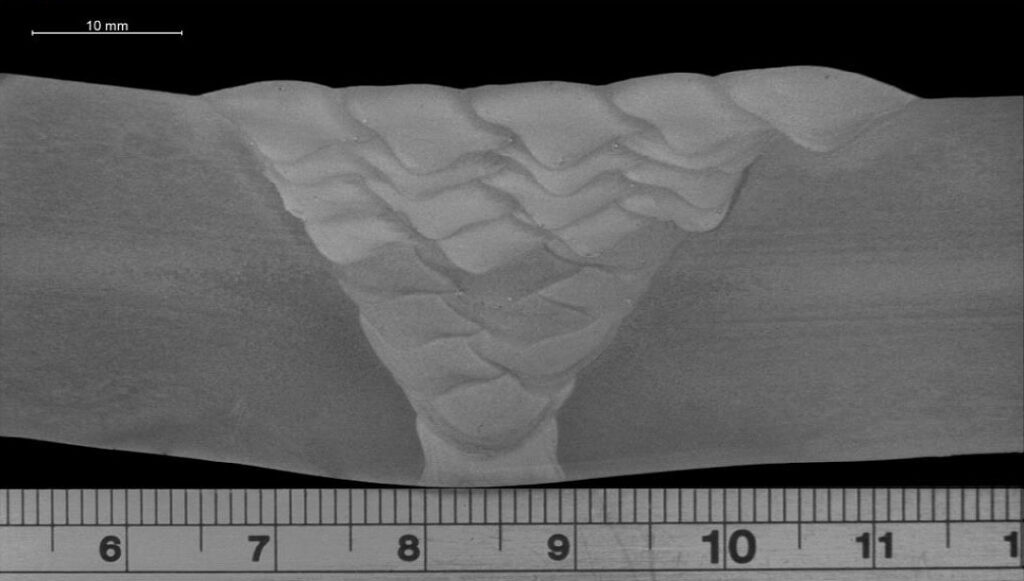

- Use of Olympus OmniScan MX2 Ultrasonic equipment to identify defects and discontinuities in welded joints.

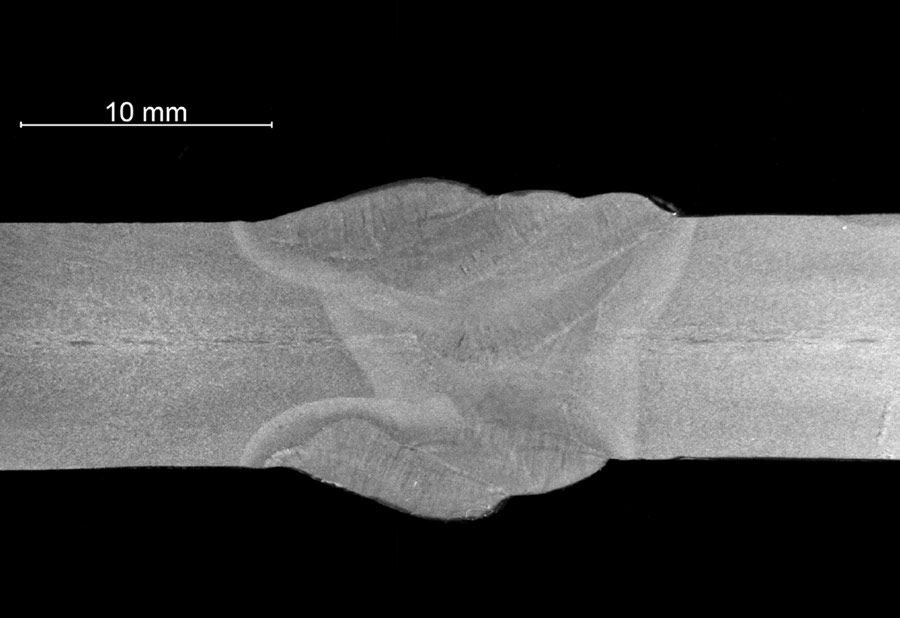

- Macroscopic technology for specimen and Mock-Up analysis, complemented by fine cutting and grinding.

- Dimensional verification with micrometers, calipers, and other high-precision instruments.

Reverse Engineering, Prototyping, and 3D Dimensional Control

Advanced 3D scanning services (ENAC calibration), Reverse Engineering, Functional Prototyping, and metrologically controlled part manufacturing.

Specific Services

3D Scanning and Reverse Engineering

- High-precision 3D scanning with HandySCAN 3D (ENAC calibration) and modeling in VXelements, SolidWorks, or CAD2D systems.

Rapid Prototyping and Functional Parts

- Markforged Two, Bambu Labs XI (FDM), and Formlabs 3L (SLA) for durable, cost-effective, or high-precision parts.

Dimensional and Quality Control

- Dimensional verification with HandySCAN 3D laser scanner and precision tools (micrometers and calipers).

Technical Consulting and Process Optimization

Project Management, Lean Manufacturing, and Technical Documentation services aligned with ISO standards.

Specific Services

- Lean Diagnostics

- Project Management

- Quality Manual drafting (ISO 9001:2015, ISO 3834-2, UNE-EN-1090).

Advanced Metrology

Fully equipped laboratory for testing and inspecting the entire production process, with trained and accredited personnel.

- HandySCAN 3D Scanner

- Tensile-Compression equipment

- Micrometers

- 3D Level Calipers and Verniers

- Olympus OmniScan SX equipment

- Macroscopic technology for identifying defect distributions or discontinuities in welded joints through Mock-Up specimen examination involving cutting and fine grinding techniques.